🛢️ Formation Damage and Mitigation

📘 Course Description Formation damage is a major cause of productivity loss in oil and gas wells, often leading to significant economic consequences. This advanced course provides a comprehensive understanding of formation damage mechanisms, their diagnosis, prevention, and effective mitigation …

Overview

📘 Course Description

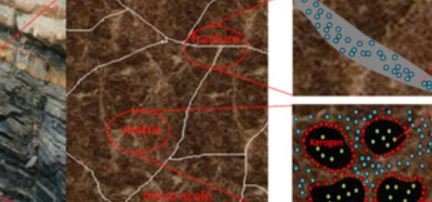

Formation damage is a major cause of productivity loss in oil and gas wells, often leading to significant economic consequences. This advanced course provides a comprehensive understanding of formation damage mechanisms, their diagnosis, prevention, and effective mitigation techniques. Participants will learn to identify potential damage during drilling, completion, production, and stimulation operations. Practical strategies and real-world case studies will enable participants to minimize formation damage and optimize well performance.

🎯 Learning Objectives

✅ Understand types and causes of formation damage

✅ Evaluate damage during drilling, completion, and production phases

✅ Analyze core and well test data for damage identification

✅ Design effective damage prevention strategies

✅ Apply chemical and mechanical remediation techniques

✅ Integrate damage mitigation with reservoir management plans

👥 Who Should Attend

-

Production and reservoir engineers

-

Completion engineers

-

Drilling engineers

-

Stimulation engineers

-

Petrophysicists

-

Field supervisors

-

Anyone involved in maintaining well productivity

🗂️ Training Format

✅ Interactive lectures with real-world examples

✅ Damage identification exercises

✅ Case studies of successful and failed treatments

✅ Group discussions to share practical experiences

✅ Worksheets for damage calculations

📅 Day-by-Day Agenda with Time Breaks

📅 Day 1: Fundamentals of Formation Damage

| Time | Topic |

|---|---|

| 08:30 – 09:00 | Welcome, Introductions & Course Overview |

| 09:00 – 10:30 | Definition, Mechanisms & Types of Formation Damage |

| 10:30 – 10:45 | ☕ Coffee Break |

| 10:45 – 12:15 | Formation Sensitivities: Clay Swelling, Fines Migration |

| 12:15 – 13:15 | 🍽 Lunch |

| 13:15 – 14:45 | Damage during Drilling: Mud Invasion & Filter Cake |

| 14:45 – 15:00 | ☕ Coffee Break |

| 15:00 – 16:30 | Damage during Completion & Perforation |

📅 Day 2: Damage During Production & Workovers

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Damage During Production: Scale, Emulsions, Asphaltenes |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Damage Due to Water & Gas Breakthrough |

| 12:15 – 13:15 | 🍽 Lunch |

| 13:15 – 14:45 | Damage in Injection Wells |

| 14:45 – 15:00 | ☕ Coffee Break |

| 15:00 – 16:30 | Well Intervention Risks & Workover-Induced Damage |

📅 Day 3: Damage Identification & Diagnosis

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Core Analysis & Laboratory Techniques |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Production Data & Pressure Transient Analysis |

| 12:15 – 13:15 | 🍽 Lunch |

| 13:15 – 14:45 | Formation Damage Indicators in Well Logs |

| 14:45 – 15:00 | ☕ Coffee Break |

| 15:00 – 16:30 | Case Studies: Diagnosing Damage in Real Wells |

📅 Day 4: Damage Prevention & Mitigation Strategies

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Drilling Fluid & Completion Fluid Selection |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Filter Cake Removal Techniques |

| 12:15 – 13:15 | 🍽 Lunch |

| 13:15 – 14:45 | Chemical Treatments: Acids, Solvents, Surfactants |

| 14:45 – 15:00 | ☕ Coffee Break |

| 15:00 – 16:30 | Mechanical & Hydraulic Methods for Damage Removal |

📅 Day 5: Integrated Damage Management & Case Studies

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Integrating Damage Mitigation in Reservoir Management |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Advanced Strategies: Proactive Damage Control Plans |

| 12:15 – 13:15 | 🍽 Lunch |

| 13:15 – 14:45 | Group Exercise: Designing a Damage Mitigation Plan |

| 14:45 – 15:00 | ☕ Coffee Break |

| 15:00 – 16:30 | Review, Q&A, Final Assessment, & Certificate Ceremony |

📦 Materials Provided

✅ Comprehensive course manual

✅ Formation damage calculation templates

✅ Real case study datasets

✅ Chemical treatment design guidelines

✅ Certificate of Completion

Target audiences

- Reservoir Engineers, Geologists

You May Like

📘 Underbalanced Drilling (UBD) Techniques and Safety

🎯 Course Description: This intensive 5-day program focuses on Underbalanced Drilling (UBD) – an advanced technique used to drill wells where the hydrostatic pressure of the fluid is intentionally kept below formation pressure. Participants will learn how to implement UBD …

📘 IOSH Managing Safely

🎯 Course Description: A practical, 5-day program designed to help managers and supervisors learn how to manage safety and environmental responsibilities in their teams. Emphasis is placed on identifying risks, measuring performance, and leading safely using internationally recognized good practices. …

📘 IWCF Level 3 Well Control (Surface BOP)

🎯 Course Description: This is an intensive course aimed at drilling / well service personnel needing to gain supervisory competence in well control using surface blow‑out preventers (BOP) under the IWCF standard. It covers theory, hands‑on practice, and assessments for …

Advanced Specialist Petroleum GeoMechanics

📘 Course Description: This elite-level course is tailored for petroleum geomechanics specialists and senior subsurface professionals engaged in complex field development projects. It provides a deep technical dive into stress modeling, anisotropic rock behavior, coupled geomechanical-reservoir simulation, fault/fracture mechanics, and …

📘 OSHA 30‑Hour General Industry Safety and Health

🎯 Course Description: This 5‑day course provides in‐depth knowledge of workplace safety and health in general industry sectors. It covers OSHA regulations, hazard recognition, safety programs, and industry best practices. Participants will gain the expertise needed to maintain a safe …