🎯 Course Description:

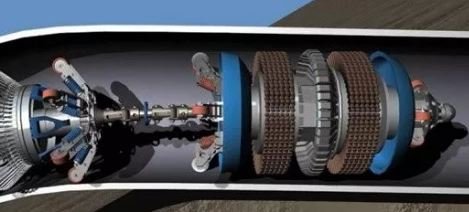

This specialized 5-day course provides comprehensive knowledge and practical skills on pipeline inspection using intelligent pigging technology. Participants will learn how to deploy, operate, and interpret data from intelligent pigs (smart pigs) for assessing pipeline integrity, detecting corrosion, cracks, deformation, and other anomalies.

The course covers the principles of various intelligent pigging tools, preparation and execution of pig runs, data analysis, and integration with pipeline integrity management programs. Real case studies and hands-on exercises with simulation software enhance learning for both field and inspection engineers.

👥 Who Should Attend:

-

Pipeline integrity engineers and inspectors

-

NDT specialists and data analysts

-

Maintenance and operations personnel

-

Pipeline project engineers and supervisors

-

Asset integrity and risk management professionals

-

Individuals preparing for pipeline inspection certification

🗓️ Day 1: Introduction to Intelligent Pigging and Pipeline Integrity

| Time | Topic |

|---|---|

| 08:30 – 09:00 | Welcome, Course Objectives, Participant Introductions |

| 09:00 – 10:30 | Pipeline Integrity Management Overview – Key concepts and regulations |

| 10:30 – 10:45 | ☕ Coffee Break |

| 10:45 – 12:15 | Introduction to Pigging – History, types of pigs, and applications |

| 12:15 – 01:15 | 🍽 Lunch Break |

| 01:15 – 02:45 | Intelligent Pigging Technologies – MFL, UT, Geometry, Caliper pigs |

| 02:45 – 03:00 | ☕ Coffee Break |

| 03:00 – 04:30 | Pipeline Preparation for Pigging – Cleaning, batching, launching systems |

🗓️ Day 2: Types of Intelligent Pigs and Their Applications

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Magnetic Flux Leakage (MFL) Pigs – Principle and defect detection |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Ultrasonic Testing (UT) Pigs – Operation and data capture |

| 12:15 – 01:15 | 🍽 Lunch Break |

| 01:15 – 02:45 | Geometry and Caliper Pigs – Detecting dents, ovalities, and deformations |

| 02:45 – 03:00 | ☕ Coffee Break |

| 03:00 – 04:30 | Practical Demo: Equipment setup and pig launching procedures |

🗓️ Day 3: Data Acquisition and Processing

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Data Acquisition Systems – Sensors, electronics, and data logging |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Data Processing Techniques – Filtering, signal processing, and software tools |

| 12:15 – 01:15 | 🍽 Lunch Break |

| 01:15 – 02:45 | Data Quality Assurance and Validation |

| 02:45 – 03:00 | ☕ Coffee Break |

| 03:00 – 04:30 | Hands-On Exercise: Simulated data interpretation |

🗓️ Day 4: Defect Identification and Analysis

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Corrosion and Metal Loss Detection – Identifying and sizing defects |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Crack and Weld Anomaly Detection – Using UT and MFL data |

| 12:15 – 01:15 | 🍽 Lunch Break |

| 01:15 – 02:45 | Pipeline Geometry Anomalies – Dents, buckles, and ovality analysis |

| 02:45 – 03:00 | ☕ Coffee Break |

| 03:00 – 04:30 | Case Studies: Real-life intelligent pigging inspection reports analysis |

🗓️ Day 5: Reporting, Integration, and Field Practices

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Inspection Reporting – Structure, key elements, and compliance |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Integration with Pipeline Integrity Management Programs |

| 12:15 – 01:15 | 🍽 Lunch Break |

| 01:15 – 02:45 | Field Operations and Safety – Launchers, receivers, and pig tracking |

| 02:45 – 03:00 | ☕ Coffee Break |

| 03:00 – 04:30 | Final Assessment and Q&A; Certificate Distribution |

📂 Materials Provided:

-

Intelligent Pigging Technologies Handbook

-

Data Interpretation Guides and Software Tools Overview

-

Inspection Reporting Templates

-

Case Study Workbooks

-

Field Safety and Operation Procedures

-

Certificate of Completion