🎯 Course Description:

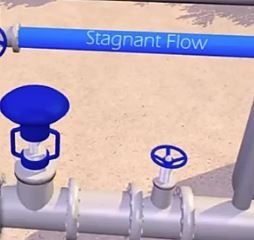

This specialized training course provides participants with a thorough understanding of dead legs in piping and process systems, their risks, and effective management strategies. The course focuses on identifying, assessing, and mitigating the operational and safety hazards caused by dead legs, particularly in industries such as oil & gas, petrochemical, water treatment, and pharmaceuticals.

Participants will learn best practices for dead leg identification, risk evaluation, system design modifications, inspection, and maintenance to minimize contamination, corrosion, and operational inefficiencies.

👥 Who Should Attend:

-

Process engineers and pipeline designers

-

Inspection and maintenance personnel

-

Corrosion and integrity engineers

-

Quality assurance and compliance professionals

-

Plant safety and risk managers

-

Asset integrity and operations personnel

🗓️ Day 1: Introduction to Dead Legs and Associated Risks

| Time | Topic |

|---|---|

| 08:30 – 09:00 | Welcome, Course Overview, Participant Introductions |

| 09:00 – 10:30 | What is a Dead Leg? – Definition, causes, and common examples |

| 10:30 – 10:45 | ☕ Coffee Break |

| 10:45 – 12:15 | Risks and Consequences – Contamination, corrosion, microbial growth, and safety hazards |

| 12:15 – 01:15 | 🍽 Lunch Break |

| 01:15 – 02:45 | Dead Leg Classification and Regulatory Requirements |

| 02:45 – 03:00 | ☕ Coffee Break |

| 03:00 – 04:30 | Case Studies: Incidents caused by dead legs |

🗓️ Day 2: Identification and Mapping of Dead Legs

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Systematic Identification Methods – Drawing review, flow analysis |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Dead Leg Mapping Tools and Software |

| 12:15 – 01:15 | 🍽 Lunch Break |

| 01:15 – 02:45 | Practical Session: Mapping dead legs on sample piping layouts |

| 02:45 – 03:00 | ☕ Coffee Break |

| 03:00 – 04:30 | Workshop: Prioritization based on risk and operational impact |

🗓️ Day 3: Risk Assessment and Management Strategies

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Risk Assessment Methodologies – Qualitative and quantitative approaches |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Mitigation Techniques – Flushing, pigging, insulation, and design changes |

| 12:15 – 01:15 | 🍽 Lunch Break |

| 01:15 – 02:45 | Dead Leg Reduction by Design Optimization |

| 02:45 – 03:00 | ☕ Coffee Break |

| 03:00 – 04:30 | Group Exercise: Developing dead leg management plans |

🗓️ Day 4: Inspection, Monitoring, and Maintenance

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Inspection Techniques for Dead Legs – Visual, ultrasonic, corrosion monitoring |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Maintenance Procedures – Cleaning, pigging, and isolation best practices |

| 12:15 – 01:15 | 🍽 Lunch Break |

| 01:15 – 02:45 | Integration with Asset Integrity Programs |

| 02:45 – 03:00 | ☕ Coffee Break |

| 03:00 – 04:30 | Hands-On Workshop: Creating inspection and maintenance schedules |

🗓️ Day 5: Reporting, Compliance, and Continuous Improvement

| Time | Topic |

|---|---|

| 08:30 – 10:00 | Documentation and Dead Leg Reporting |

| 10:00 – 10:15 | ☕ Coffee Break |

| 10:15 – 12:15 | Compliance with Industry Standards and Regulations |

| 12:15 – 01:15 | 🍽 Lunch Break |

| 01:15 – 02:45 | Continuous Improvement and Lessons Learned |

| 02:45 – 03:00 | ☕ Coffee Break |

| 03:00 – 04:30 | Final Q&A, Feedback, Course Wrap-Up, and Certificates |

📂 Materials Provided:

-

Dead Leg Management Handbook

-

Mapping and Risk Assessment Templates

-

Inspection and Maintenance Checklists

-

Case Studies and Incident Reports

-

Regulatory and Compliance Guidelines Summary

-

Certificate of Completion